23/09/2025

05 STANDARD STEPS FOR ERECTING A PRE-ENGINEERED STEEL BUILDING

Pre-engineered steel buildings are one of the most efficient construction methods in terms of both schedule and cost. With a construction time reduced to just one-third compared to conventional reinforced concrete structures, the fabrication and erection process of a pre-engineered steel building goes through five main stages: foundation bolt installation, main frame erection, roof sheeting installation, wall sheeting installation, and finishing works.

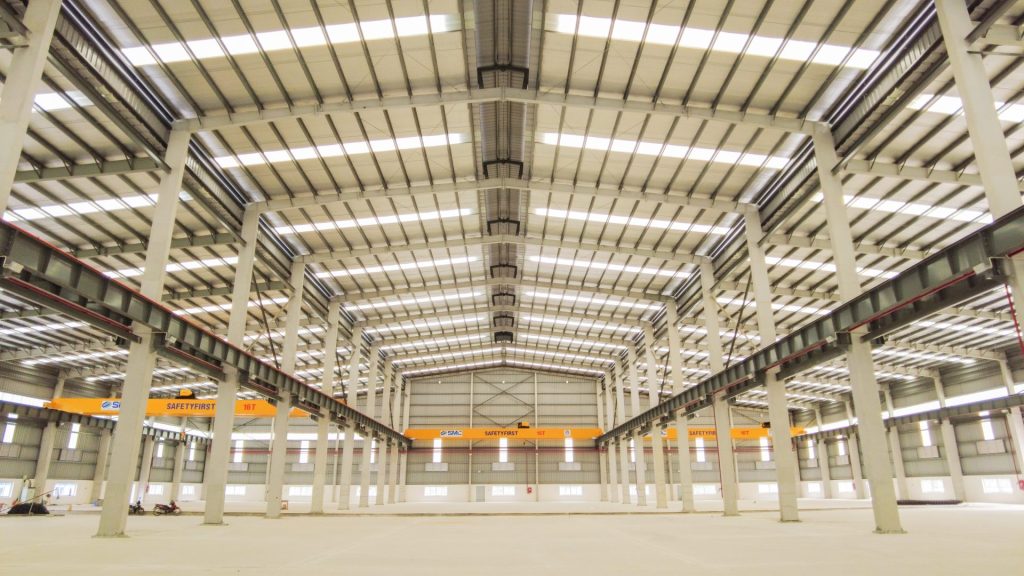

SMC plant

Before erection begins, site preparation is essential: the storage area must be large, clean, and compacted enough for crane movement. Necessary equipment includes cranes, steel wire ropes, steel drills, concrete drills, bolt wrenches, and rivet guns.

Step 1: Foundation Bolt Installation

Anchor bolts must be positioned precisely according to the design grid lines and elevations. Bolts must be securely welded in clusters to prevent displacement during concrete pouring.

Correct placement as per shop drawings is mandatory to ensure alignment with the superstructure. The spacing within and between bolt groups must strictly comply with allowable tolerances specified in steel structure erection standards.

Foundation Bolt Installation at Raico Viet Nam plant

Step 2: Main Frame Erection

This is the most critical phase, as the first column and rafter set the alignment for the entire building. Depending on site conditions, erection can start from the center bay outward or from one end bay.

Main Frame Erection at F Warehouse (Hoa Phat Dung Quat)

- Step 1: Check foundation bolt positioning and crane paths.

- Step 2: Erect the first rafter frame. Connect bracing and purlins before hoisting. As soon as the rafter is lifted off the ground, ensure stability and check bolt torque and vertical alignment before final tightening.

- Step 3: Erect the first rigid frame (with bracing system). Repeat the process for the second frame. Install 100% of roof purlins in the first bay, along with wall and roof bracing. Adjust alignment carefully before tightening anchor bolts, column-to-rafter bolts, and bracing bolts.

- Step 4: Continue erecting subsequent frames using the same procedure.

- Step 5: Complete the main frame erection by installing all purlins, rafters, bracing, and struts. Final alignment must be checked before roof sheeting.

Step 3: Roof Sheeting Installation

Just like the main frame, the first roof sheet must be installed with utmost care, as it determines the alignment of subsequent sheets. Marking lines for each sheet ensures lap joints remain straight and perpendicular to the purlins. After roof sheeting, ridge caps, flashing, and trim are installed to enhance waterproofing and aesthetics.

For projects with insulation, it must be installed carefully to ensure straight joints, no stretching, and a flat, wrinkle-free finish underneath.

- Roof Sheeting Installation

- Projects with insulation

Step 4: Wall Sheeting Installation

Wall sheeting follows similar steps as roof sheeting but is generally simpler due to shorter spans. Close coordination with the civil contractor is required to ensure seamless integration. Wall sheeting includes trims and flashings such as corner trims, base trims, door and window flashings, and louvers, providing both weather tightness and aesthetic value.

Wall Sheeting Installation at Long Thanh plastic factory

Step 5: Finishing Works

The final stage requires meticulous inspection. All bolts must be re-checked, gaps at sheet overlaps and around openings sealed to prevent leakage. Door installation is also carried out at this stage. Ensuring accuracy and completeness here guarantees long-term performance and quality of the project.

Long Thanh plastic factory

Contact information:

– HA GIANG PHUOC TUONG STEEL JSC (HGPT Steel)

– H.O. & Workshop: No.8 street, Hoa Cam Industrial Zone, Da Nang

– Hotline: 0949.386.113

– Mail: info@hgpt.vn – Website: https://hgptsteel.com/

– Fanpage: https://www.facebook.com/HGPTMechanicalJSC

Subscribe to HGPT STEEL Newsletter

Get the latest updates on projects, products, and company activities from HGPT STEEL. Take a look

Related news

CONTACT US NOW

We are committed to partnering with businesses, contractors, and investors to deliver projects of quality – sustainability – and on schedule.