20/05/2025

HGPT Steel conquered a steel structure frame with a span of over 100 meters

Steel structural frames with a span of over 100 meters require high precision and sophisticated fabrication techniques. To create a strong and stable steel truss system, every stage — from pipe bending and assembly to welding — must be carried out meticulously, ensuring that each detail meets technical standards.

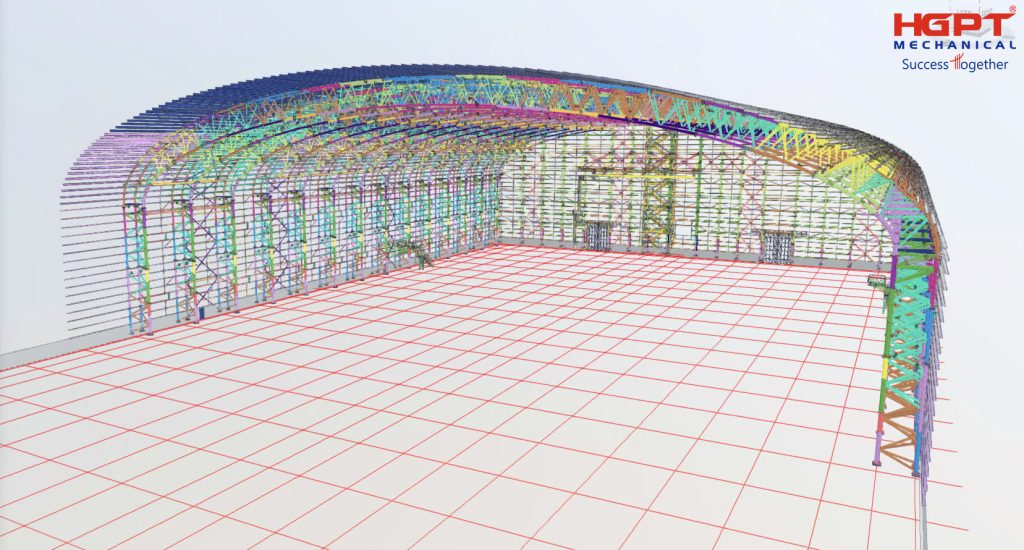

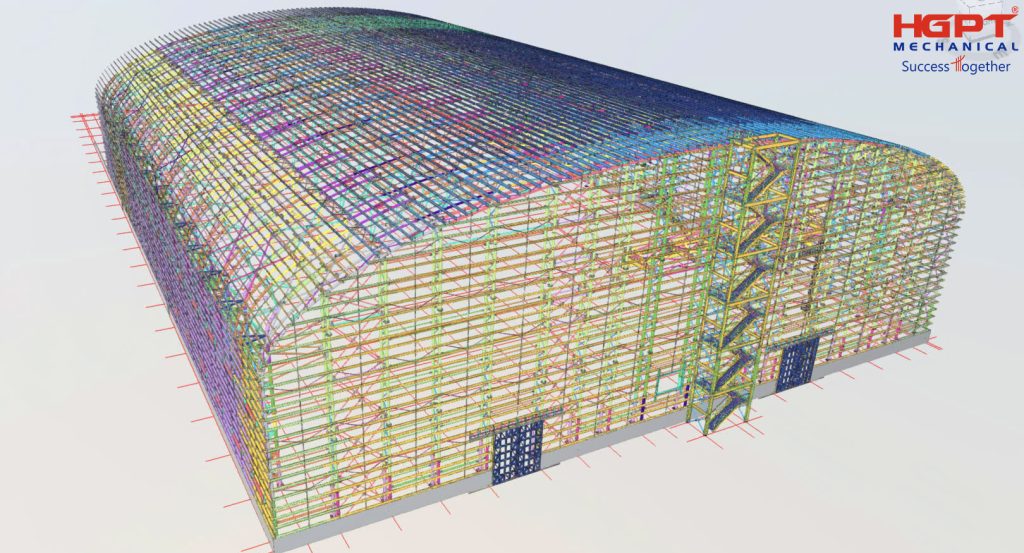

- Steel structure frame drawing

- Steel structure frame drawing

With outstanding advantages:

1. Precision fabrication – Steel members are bent into complex curves with the smallest tolerances.

- HGPT’s steel pipe bending machine

- Pipe bending with large span capacity

2. High-quality welding – Connecting hundreds of components with uniformity and excellent load-bearing capacity.

- Welders of steel structural components

- Welders of steel structural components

3. Optimized structure – An intelligently designed steel truss system that ensures safety, aesthetics, and the ability to withstand heavy loads.

- Steel structural frame being shot blasted for cleaning

With experience and advanced technology, HGPT Mechanical delivers durable, high-quality products that meet the highest standards, contributing to the success of every project.

- Painting steel structural frames

- Ensuring coating quality meets standards

- Dispatching steel structural frames

Contact information:

– HA GIANG PHUOC TUONG STEEL JSC (HGPT Steel)

– H.O. & Workshop: No.8 street, Hoa Cam Industrial Zone, Da Nang

– Hotline: 0949.386.113

– Mail: info@hgpt.vn – Website: https://hgptsteel.com/

– Fanpage: https://www.facebook.com/HGPTMechanicalJSC

Subscribe to HGPT STEEL Newsletter

Get the latest updates on projects, products, and company activities from HGPT STEEL. Take a look

Related news

CONTACT US NOW

We are committed to partnering with businesses, contractors, and investors to deliver projects of quality – sustainability – and on schedule.