25/09/2025

What is Steel Purlin? Overview of Steel Purlins

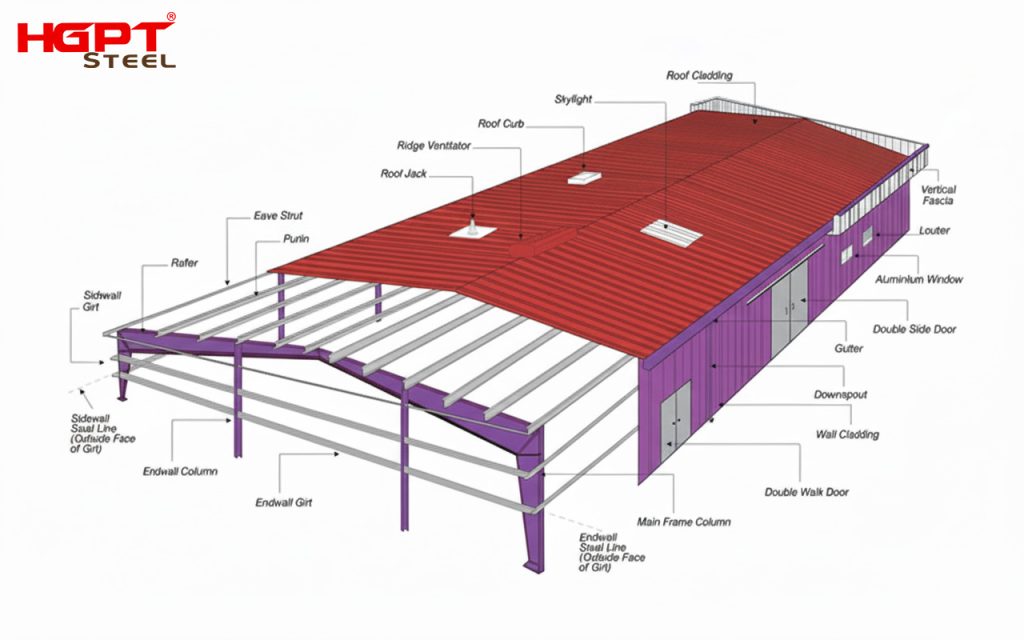

A purlin is a commonly used term in architectural and structural design. It is a component of the roof structural system. In practice, purlins come in many shapes and types. In this article, we will focus specifically on steel purlins used in pre-engineered steel buildings.

Steel purlins

Steel purlins are purlins manufactured from steel. They may have solid round or rectangular tube shapes and are widely used in the construction industry. Compared to other purlin materials, steel purlins offer high durability, rigidity, and excellent load-bearing capacity.

Shapes of Steel Purlins

Steel purlins can be produced in solid round or rectangular hollow form. Their dimensions vary depending on the structural and design requirements.

Steel purlins are commonly classified into three main types: C-shaped steel purlins (C-Purlin), Z-shaped steel purlins (Z-Purlin), Rectangular/Hollow Structural Steel Purlins (HSS Purlin)

C-Purlin

C-purlins are C-shaped steel members placed horizontally and used to support roof loads or cladding systems. Their flat side makes them ideal for fastening to steel or concrete frames, ensuring easy installation. C-purlins are lightweight and suitable for short to medium-span structures, commonly used in factories with 6m column spacing.

<Commonly used for factory buildings with column spacing 6m

Typical Specifications:

– C200x50x20x1.8: C-purlin with 200mm web height, 50mm flange width, 20mm lip, and 1.8mm thickness.

– C150x50x20x1.5: C-purlin with 150mm web height, 50mm flange width, 20mm lip, and 1.5mm thickness.

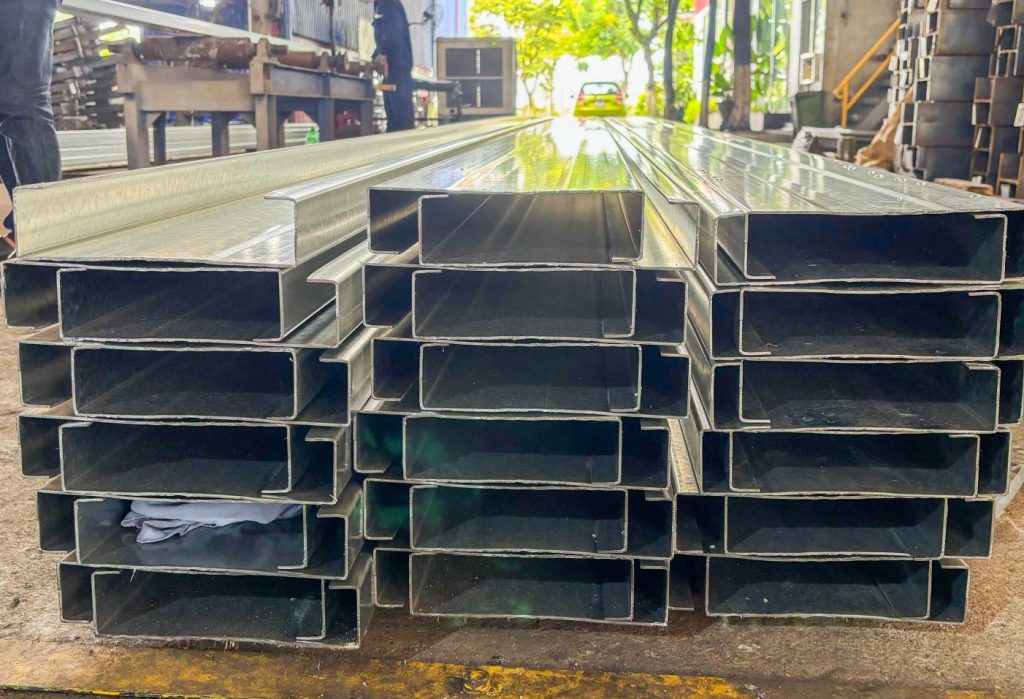

C-Purlins Manufactured by HGPT STEEL

Z-Purlins

The Z-shaped profile allows Z-purlins to overlap at joints, giving them greater load-bearing capacity compared to C-purlins. They are mainly used for wall framing and large-span roofing projects.

Z-purlins are suitable for larger column spacing because the overlapping joint increases structural strength and reduces deflection.

Typical Specifications:

– Z200x72x78x2.0: Z-purlin with 200mm web height, 72mm and 78mm flange widths, and 2.0mm thickness.

– Z200x62x68x1.8: Z-purlin with 200mm web height, 62mm and 68mm flange widths, and 1.8mm thickness.

Z-Purlins Manufactured by HGPT STEEL

Hollow Structural Steel Purlins (HSS Purlins)

HSS purlins are also commonly used today. They are often applied in roofed platforms, walkways, and canopy structures. Since these sections are hollow, end caps are welded to seal the ends, preventing moisture accumulation and reducing internal corrosion.

The rectangular profile of HSS purlins provides a clean and aesthetically pleasing roof appearance, similar to wooden-supported roofing systems.

Source: Internet

Advantages of Steel Purlins

Steel purlins offer high durability and rigidity, allowing them to withstand heavy loads and various environmental conditions. In addition, steel purlins have excellent structural performance, enabling buildings to resist external forces effectively.

Applications of Steel Purlins in Construction

Steel purlins are widely used in various construction projects, including:

– High-rise construction: Used to form structural members supporting vertical and roof loads.

– Bridge and roadway construction: Used for beams and load-bearing framing in bridges and infrastructure.

– Industrial factory construction: Applied as structural framing components in factory and warehouse buildings.

Steel Purlins Installed by HGPT at Long Thanh Plastic Plant Project

Conclusion

Steel purlins are one of the essential materials in the construction industry, offering advantages such as high durability, rigidity, and strong load-bearing capacity. However, during use, regular inspection and maintenance are necessary to ensure structural safety. Steel purlins are widely applied in various construction fields, from high-rise buildings to bridges and industrial factories. Proper installation procedures must be followed to ensure accuracy and safety. With their proven advantages, steel purlins will continue to be widely used in the construction industry in the future.

If you are looking for a reliable and strong structural material, steel purlins are an excellent choice. Due to their high durability, strength, and load-bearing performance, they are widely used in major and critical construction projects.

Therefore, it is important to select the most suitable purlin type for your application and always follow standard installation and safety procedures in construction.

Contact information:

HA GIANG PHUOC TUONG MECHANICAL JSC (HGPT Steel)

Address: Street No. 8, Hoa Cam Industrial Zone, Hoa Tho Tay Ward, Cam Le District, Da Nang City

Hotline: 0949.386.113

– Mail: tender@hgpt.vn – Website: https://hgptsteel.com/

– Fanpage: https://www.facebook.com/HGPTMechanicalJSC

Subscribe to HGPT STEEL Newsletter

Get the latest updates on projects, products, and company activities from HGPT STEEL. Take a look

Related news

CONTACT US NOW

We are committed to partnering with businesses, contractors, and investors to deliver projects of quality – sustainability – and on schedule.